Roofing battens – what to look out for?

The NFRC (National Federation of Roofing Contractors) has advised that due to the high demand for treated timber, there is now an abundance of sub-standard roofing battens within the UK market that are being marked, coloured and sold as compliant to BS 5534, when in fact they may be counterfeit. These sub-standard goods are becoming an increasingly serious issue for merchants, roofing contractors and their clients.

Using non-compliant battens may result in the contractor having to strip and re-roof a property should the battens be proven to be substandard, and a significant health and safety risk may be created by the contractor using non-compliant battens as a foothold as this is in contravention to the guidelines set out in HSE guidance HSG33: Health and Safety in Roof Work. Using battens that have an inferior quality to certified roofing battens may reduce the longevity of the roof and can potentially put roofing operatives at risk of harm.

What to look out for?

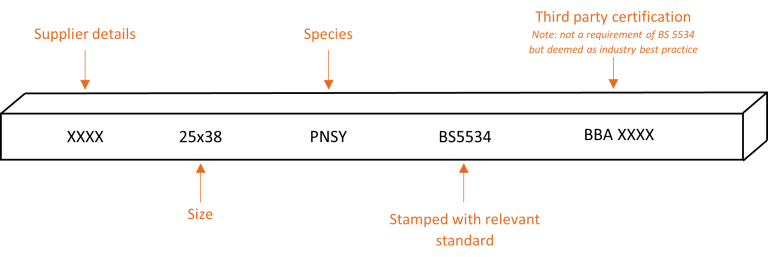

BS 5534 is the code of practise for slating and tiling pitched roof and vertical cladding. It states in paragraph 4.11.5.2 of BS 5534 that each batten should be “indelibly marked” with the following information:

a) supplier

b) origin (imported or British-grown, and/or species code)

c) “graded BS 5534” - marking BS 5534 on the batten represents a manufacturer’s declaration of conformity

d) size

Figure 1: Elements marked on a BS 5534 compliant batten.

However, marking alone is not proof that the batten has been graded correctly or that it is of the correct standard, so there are a few simple steps that can be taken as follows:

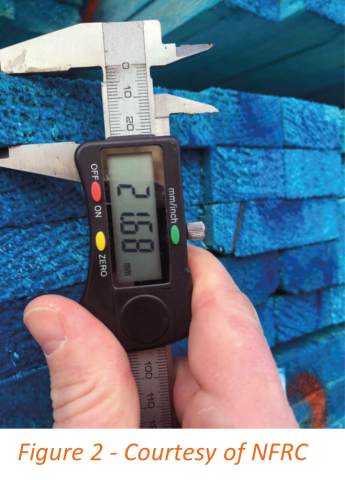

1. Check the thickness of the batten, as BS 5534 states that a batten should be 25mm thick with a tolerance of -0/+3 mm. Therefore, a roofing batten less than 25mm should not be purchased or used – see Figure 2. Also, unequal thicknesses of roofing battens visible in a stack may be a sign of substandard battens – see Figure 3.

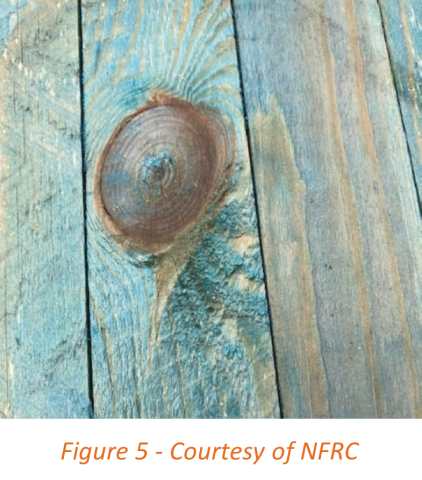

2. Check to see if any knots are present. BS 5534 states that the sum of a knot on both faces can be no more than the width of the batten, i.e. 38 mm/50 mm. Therefore, if a knot is visible on both sides of a batten, when added together the overall size should not be more than 38mm or 50mm, depending on the batten. Figure 4 and 5 shows images of battens with excessive knots, that should not be used.

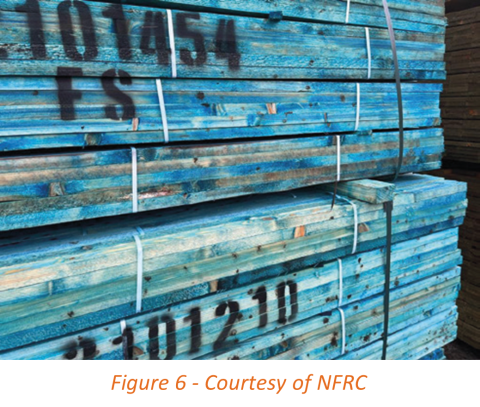

3. Do not rely on the colour of a roofing batten to guarantee that it is compliant. Over the years, different manufacturers have coloured their battens as a visual aid to prove compliance, but the organisations that supply substandard products are also aware of this and colour their battens. Figure 6 shows marked coloured battens, but they do not conform to BS 5534 – and indicator of this is that the battens are not individually marked.

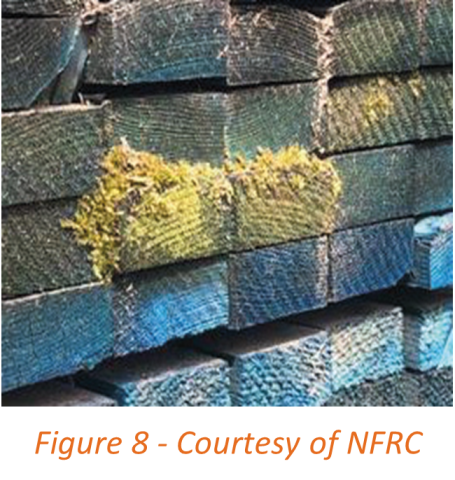

4. BS 5534 graded battens should not rot. If you see signs of rot, decay or growth on a batten, do not use it – see Figures 7 and 8.

5. Documentation. All roofing battens that are compliant with and graded to the requirements of BS 5534 will either be delivered to site with the correct documentation, or the documentation should be available from the merchant. Always request a copy of this documentation and any third-party certification, and retain these records.

Health and Safety

The use of inferior battens that do not comply with BS 5534 has the potential to cause roof failures and accidents. This risk of accidents increases when the roof battens are being used as an alternative to a roof ladder and are therefore taking the additional live load of the operative installing the roof.

HSE guidance, HSG33 Health and Safety in Roof Work, states that timber battens may provide a reasonably secure foothold if they:

- have a minimum size of 50mm x 25mm (maximum span 600mm) or 38mm x 25mm (maximum span 450mm)

- meet the grading requirements specified in BS 5534 - Code of practice for slating and tiling and NFRC Technical Bulletin 33 - Graded Battens for Slating and Tiling

Non-compliant battens should not be installed. Ungraded battens may prove weak and vulnerable to failure should the roofer inadvertently walk on these areas whilst covering the roof.

When using battens as footholds, the weight of the roofer must always be on or as close as possible to the rafter/batten junction where the fixings are. The roofer’s foot should be above the rafter wherever possible, rather than on the batten and under no circumstance should the roofer deliberately walk mid-span on battens with open rafters.

The battens should also be specified and installed by a competent person in accordance with the tiling and/or slate manufacturers recommendations

NOTE: Every care was taken to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the dutyholder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

Appalling Standard of Roofing generally

Submitted 1 year 5 months ago

Why ?

Roofing battens – what to look out for?

Submitted 1 year 4 months ago

I had understood the there was a 'Roofing CPS'.

I'm not sure where the material for this article comes from (Trading Standards?) but how can this issue be policed by regulators such as Building Control. Only impromptu intervention by a visiting RBI may occur if at the time of any other type inspection it is noted that the traditional 'blue' is in fact an inappropriate or snide roof batten

LABC Response

Submitted 1 year 3 months ago

Installation, as a replacement, of the covering of a pitched roof and work carried out by a registered person as a necessary adjunct to that installation is still part of the competent person self-certification process defined in building regulations. In order to be registered, roofing contractors have to evidence their competency and the competent person scheme operators have a surveillance role to check that their registrants are complying with building regulations, which will include the use of proper materials. Where re-roofing work is not carried out under such a scheme or where the roof forms part of a new structure, building control will have oversight of the project, which, from April, should be a registered building inspector (RBI).

Best,

LABC Team

Ychwanegu sylw newydd