How to get it right: Parapet walls

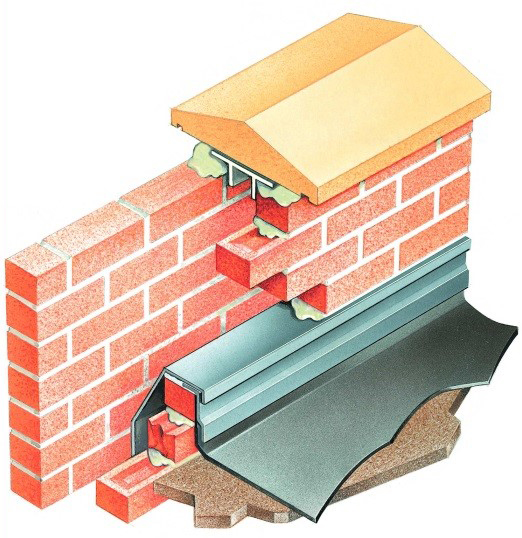

Parapet walls behave differently to conventional cavity walls because of their location at the very top of a building where both skins of the parapet are outer skins, and as such are exposed to moisture.

Traditionally constructed parapet walls can become saturated with rain and are also subject to extremes of heat and cold, leading to expansion of the masonry.

When this occurs the damp proof course (DPC) course in a parapet offers the line of least resistance and acts as a slip plane, so movement at DPC level in the outer and inner skins is common.

Where the amount of expansion is not fully compensated by contraction, progressive movement over the years will occur. This is mainly as a result of ‘ratcheting’ (where the expansion movement is not fully matched by the retraction movement, and masonry above and below the DPC progressively moves out of alignment).

Where the amount of expansion is not fully compensated by contraction, progressive movement over the years will occur. This is mainly as a result of ‘ratcheting’ (where the expansion movement is not fully matched by the retraction movement, and masonry above and below the DPC progressively moves out of alignment).

This is easily identified first by witness lines and eventually by horizontal cracking along the courses in which the parapet DPC has been supported, as you can see in the photo.

A spokesman for tray manufacturer Cavity Trays of Yeovil explained:

“Originally the British Standard showed an inward stepping DPC rather than an outward one and at first, parapet walls built to that detail functioned correctly.

“But it only takes a few years before parapet cracking occurs, and eventually water will permeate the outer skin along the DPC bedding joint and track inwardly on the underside of that inward stepped DPC.

“As soon as that tracking reaches the inner skin, the damp problem becomes visible.”

Cavity Trays of Yeovil explains that their approach was the opposite. They designed an outward stepping arrangement - the concept subsequently adopted within the latest British Standard.

However, an alternative approach using a preformed parapet ‘Cavitray’ that is self-supporting and only needs to be built into one skin, offers lots of advantages. The requisite outward stepping profile is achieved but the opposite masonry skin can remain uninterrupted and as such, the structural integrity is significantly improved. The parapet tray is called Type P.

Parapet walls need not be problematic. The right specification ensures a correctly protected structure and one in which the structural continuity isn’t hindered by DPC slip-planes.

Further information

http://www.cavitytrays.co.uk/damp-proofing/view/1/32/1/type-p-cavitray

http://www.cavitytrays.co.uk/pdf/32-Type-P.pdf

Please Note: Every care was taken to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the dutyholder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

(No subject)

Submitted 6 years 6 months ago

Many thanks Ted Nelson

(No subject)

Submitted 6 years 6 months ago

Webmaster note

Submitted 6 years 6 months ago

Parapet Wall Cold Flat Roof

Submitted 4 years 11 months ago

Any idea how we can ventilate this?

Any details?

Thank you

Joe

Reply

Submitted 4 years 10 months ago

Many thanks for your comment.

You'll need to engage the services of a professional agent with experience of the roof design you intend to use on your project. Unfortunately we aren't able to offer private design services.

Regards

Barry, LABC

Parapet Copings

Submitted 3 years 4 months ago

Ychwanegu sylw newydd