Changes to SAP 10 and how they will affect you

SAP 10 is cited in Approved Document L Volume 1: Dwellings (2012 edition) for England and is the recognised calculation methodology for assessing compliance of new dwellings with Requirement L1 of the Building Regulations. What is it all about and what are the recent changes to SAP?

What is SAP?

The Standard Assessment Procedure for the Energy Rating of Dwellings (SAP) is the UK Government’s National Calculation Methodology for assessing the energy performance of dwellings. SAP was developed by BRE and first published in 1993.

Over the years is has been updated multiple times – including 1998, 2001, 2005, 2009 and 2012. The most recent version is SAP 10.

SAP 10 calculations consider a range of factors that contribute to energy efficiency within a new dwelling, such as:

- Materials used to construct the dwelling.

- Thermal performance of the insulation used in the building fabric.

- Air permeability of the dwelling.

- Mechanical ventilation equipment.

- Efficiency and control of heating system(s).

- Solar gains through openings of the dwelling.

- The fuel used to provide space and water heating, ventilation, and lighting.

- Energy for space cooling.

- Renewable energy technologies.

SAP 10 calculations relate only to the performance of a dwelling. As a result, SAP 10 calculations are independent of factors related to the individual characteristics of the occupants, such as:

- Household size and make up.

- Ownership and efficiency of portable electrical appliances.

- Heating regimes, including patterns and temperatures.

How is SAP used to show compliance with Part L?

A new dwelling must be built to a minimum standard of energy performance. This is evaluated by comparing calculations of the performance of the ‘actual dwelling’ against calculations of the performance of a theoretical dwelling called the ‘notional dwelling’. This must be carried out both at the design stage and when the work is complete.

The notional dwelling is the same size and shape as the actual dwelling and has standardised properties for fabric and services. The full properties of the notional dwelling are set out in SAP 10.

Approved Document L Volume 1: Dwellings (2012 edition) states that the energy performance of the notional dwelling is described using the following metrics:

- The target primary energy rate, measured in kWhPE/m2/year. The primary energy rate is influenced by the performance of both the fabric and fuel. It's calculated based on the annual primary energy use of the dwelling (per unit floor area) for space heating, water heating, ventilation, and lighting. The primary energy rate can be offset if any renewable primary energy is generated onsite.

- The target emission rate, measured in kgCO2/m2/year. The emission rate is influenced by the performance of both the fabric and fuel. It is calculated based on the annual CO2 emissions of the dwelling (per unit floor area) for space heating, water heating, ventilation, and lighting. The emission rate can be offset if any emissions are saved by energy generation technologies installed onsite.

- The target fabric energy efficiency rate, measured in kWh/m2/year. The fabric energy efficiency rate is influenced by the fabric only.

The target primary energy rate, target emission rate and target fabric energy efficiency rate for individual dwellings must be calculated using the reference values in Appendix R of SAP 10.

SAP 10 also calculates some other indicators of energy performance, including:

- Energy cost rating (the SAP rating). The SAP rating is based on the cost of energy used within the dwelling for space heating, water heating, ventilation, and lighting. The SAP rating is expressed on a scale of 1 to 100, where higher the number the lower the running costs. The energy costs can be offset if the dwelling generates energy onsite, therefore the SAP rating can be higher than 100 if renewable generation technologies are used.

- Environmental Impact rating (the EI rating). The EI rating is based on the annual CO2 emissions from the dwelling associated with space heating, water heating, ventilation, and lighting. The EI rating is expressed on a scale of 1 to 100, where the higher the number the better the standard. The annual CO2 emissions can be offset if the dwelling generates energy onsite, therefore the EI rating can be higher than 100 if renewable generation technologies are used.

Transitional arrangements

The use of Approved Document L Volume 1: Dwellings (2012 edition), and therefore SAP 10, took effect from 15 June 2022. However, it does not apply to work subject to a building notice, full plans application or initial notice submitted before 15 June 2022, provided the work starts onsite before 15 June 2023. The transitional arrangements are summarised below:

|

Application date / Works commence |

Before |

After |

| Before 15 June 2023 |

SAP 2012 | SAP 10 |

| After 15 June 2023 |

SAP 10 | SAP 10 |

Table 1: Summary of transitional arrangements

Recent changes to SAP

In 2017, the Department for Business, Energy & Industrial Strategy (BEIS) released a public consultation to detail proposals to amend SAP 2012. Based on this consultation, in July 2018 the BRE published their first version of SAP 10.

The present version of SAP 10 is 10.2, and the BRE list the main changes from SAP 2012 as follows:

- Fuel prices, CO2 emissions and primary energy factors have been updated.

- The monthly variation of CO2 and primary energy factors is now taken into consideration.

- The calculation of hot water consumption has been adjusted to take account of the shower flow rate.

- The calculation of lighting energy has been updated to allow for the lighting efficacy and amount.

- The treatment of distribution loss factors associated with communal heating networks has been revised.

- The air flow rates associated with chimneys and flues have been updated.

- The treatment of mechanical ventilation system heat recovery and aerodynamic performance has been revised.

- Additional flow temperature options have been provided for heat pumps and condensing boilers and a means.

- To recognise hybrid heat pump/boilers added.

- The self-use factor for electricity generated by photovoltaic (PV) systems has been revised and allows for the effects of battery storage and PV diverters.

- The ability to include solar thermal space heating has been added.

- The assumed standard heating pattern has been adjusted to better match UK practice.

- Provision has been made to include heat interface units (for heat networks), new heating controllers and additional fuels in the PCDB

- The reference building characteristics have been updated

- Results from low pressure pulse testing have been allowed for in the calculation of infiltration rate.

- Appendix P (summer gains check) has been removed.

- The efficiency of waste water heat recovery systems has been made to vary with shower flow rate.

Some of these changes will now be considered in slightly more detail.

Fuel prices and CO2 emissions

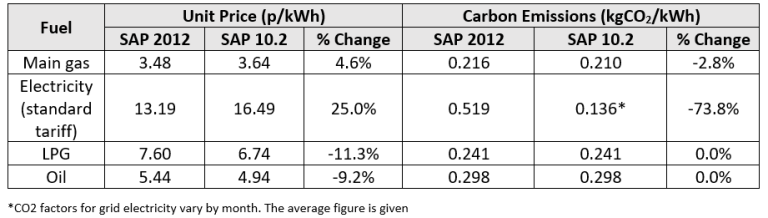

Table 2 below summarises the changes relating to assumed unit price of energy and their associated CO2 emission.

Table 2: Fuel prices and CO2 emissions

What does this mean for you?

SAP 10.2 has significantly reduced the carbon emissions of electricity to 0.136 kgCO2/kWh (averaged over a year) – this is a reduction of 73.8% over the emissions assumed in SAP 2012. This reflects the increased influence of renewable energy technologies producing electricity for the national grid and its continued de-carbonisation. When considering the most widely accessible fuel sources available to occupants of dwellings, this now means that electricity is considered one of the least carbon intensive fuel sources.

SAP 10.2 calculates fuel prices by averaging them over the previous three years and across regions. However, the Government indicated, in the Future Homes Standard Consultation that they may consider making changes to future versions of SAP to ensure that fuel prices are updated annually. This is particularly important given the recent fuel inflation.

Thermal bridging

In SAP 2012, there were three options for calculating thermal bridging, as detailed below:

- Use a global factor (a ‘y-value’ of 0.15 W/m²K), which was multiplied by the dwelling’s total exposed surface area,

- Entering the length of each junction only, which is multiplied by a default Ψ-value for that junction type, or

- Entering both the length and Ψ-value of each junction.

SAP 10.2, has updated the above options as detailed below:

- In a ‘performance gap’ study, it was noted that it is possible to design a building where using the more detailed Ψ-value approach gives a worse resulting heat loss than would be obtained using the default y-value (0.15 W/m²K). In this case there would be a temptation to use the latter approach,therefore, the y-value global factor has been increased to 0.20 W/m²K to make this situation much less likely to arise.

- The ‘default’ values have been reviewed and updated. The new values are purposely pessimistic. They are based on the worst performing example of each type in common use to encourage the assessor / housebuilder to move towards assessing each detail separately (or utilising accredited construction details or other sources – see bullet point below) – helping to close the performance gap.

- The removal of adopting the Part L ‘Accredited Construction Details’, which were developed in 2002, as they are out of date. However, the use of details from a reputable non-government database containing independently assessed thermal junction details can now be used.

Further details on changes to thermal bridging in SAP 10.2 can be found in the SAP 10 Technical Paper (S10TP-05) published by BRE.

What does this mean for you?

Designers and builders will be encouraged to calculate the actual junctions and resultant thermal bridging details, rather than using the default Ψ-values.

Photovoltaic panels (PV)

SAP 10.2 now has the option to model that any electricity generated from onsite PV panels can be stored in a battery. This allows some of the electricity generated to be used within the dwelling later if it cannot be used immediately.

Furthermore, if no battery storage is present, SAP 10.2 allows for PV diverters to be modelled. PV diverters are devices which divert electrical energy from PV panels to heat water using an electric immersion heater in a hot water cylinder. Such energy is surplus to the instantaneous electrical demand of the dwelling and would otherwise be exported to the electricity grid.

PV diverters increase the amount of PV generation that can be used within the dwelling and reduce running costs to the householder by offsetting the use of the main water heating system (e.g., a gas boiler). However, it should be noted, to maximise the diversion of electricity, a dwelling with a PV diverter may store water at a higher temperature than typical practice. This could also increase cylinder heat losses – this is reflected in applying a correction factor of 0.9.

What does this mean for you?

Installation of modern technologies, such as batteries and PV diverters can now assist with demonstrating compliance with Part L of the Building Regulations and savings can be recognised within the SAP calculation methodology.

Overheating risk

SAP 2012 provided a simplified methodology for assessing potential high internal temperatures in hot weather within the dwelling. However, this has been removed from SAP 10.2.

The requirement to now limit unwanted solar gains in summer and providing an adequate means of removing excess heat from the indoor environment is now controlled under Part O of the Building Regulations. Approved Document O (2021 edition) provides guidance that compliance can be demonstrated by using one of the following methods:

- Use a simplified method for limiting solar gains and providing a means of removing excess heat, as set out in the Approved Document, or

- Use a dynamic thermal modelling method to CIBSE’s TM59.

What does this mean for you?

A further more detailed, assessment beyond SAP is now required to demonstrate that dwellings will limit unwanted solar gains in summer and has adequate means of removing excess heat from the indoor environment.

Thermal mass parameter

Thermal mass is an attribute of the mass of the building which enables that building to store heat. Thermal mass can be a contributing principle in delivering energy performance. Thermal Mass Parameter (TMP) is a reference to the total thermal mass of the building based on its construction and is defined in SAP as the sum of (area times heat capacity) over all construction elements divided by total floor area.

In SAP 2012, where the details of the thermal mass of construction were not known precisely, an indicative value (low, medium or high) of TMP could be used instead of a detailed calculation. However, in SAP 10.2 the TMP is now required to be obtained by calculation from the actual construction elements of walls, floors, and roofs (including party and internal walls, floors, and ceilings) and kappa values as detailed in BS EN ISO 13786.

What does this mean for you?

SAP 10.2 requires the TMP to be calculated for the actual construction of the dwelling. For some designs, this may improve the energy performance of a dwelling; but for others it may not. Either way, it will improve the accuracy of modelling the energy performance of dwellings.

Future developments - SAP 11

In 2020, the Government commissioned a scoping project for the next version of SAP (called SAP 11) - to advise on how it can be enhanced to support net zero commitments for dwellings.

A consortium led by Etude carried out the SAP 11 scoping project which made several recommendations, including how to make SAP more accurate, robust and fit for purpose to support the net zero commitment.

In October 2021, the Government appointed a consortium of experts led by BRE to develop and test SAP 11. SAP 11 is likely to come into force in 2025, alongside the Future Homes Standard update of the Building Regulations.

Please Note: Every care was taken to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the dutyholder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.

This article was first published on 24 November 2022

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

Double glazing and electric water heating, waste water heat

Submitted 2 years 6 months ago

If I have double glazing, no matter how bad it is ( or even blown units) the epc assessment will only improve marginally if I fit high spec A++ double ( u 1.4 )or triple glazing ( u 1-1.2 ) Together with blow loss frames, surely this improvement will be a significant change in energy consumption?

If I have an all electric property with a bath, the water heating is an issue. If it has a 40 year old bare copper combination cylinder (most common), and replace it with a mains pressure super insulated, digital controlled storage cylinder, then again this will hardly effect the EPC. Surely yet another major energy saving measure?

I have looked at on demand water heating, but in nearly all cases they have too slow a flow rate, or/and would need major upgrades to the electrical systems in the property. Having checked with the EPC assessors, these would be poorly rated anyway.

Waste water heat recovery is surely only any good with electric showers or demand boilers, how do you assess them when you have stored hot water systems?

LABC Response

Submitted 2 years 6 months ago

Thank you for your enquiry, however, this is not something that LABC can help with. We recommend you discuss this matter with your energy assessor.

Best,

LABC Team

Ychwanegu sylw newydd