Understand BS 5534 changes to roof underlay

There’s been a big change in the way that breather membranes are installed thanks to a new code of practice, which details design standards, performance, and installation of pitched roofs. Just selecting a roofing membrane off the shelf is no longer an option – membranes must be suitable for the type and location of the building.

Parts of BS 5534 were changed from 1 March 2015 and the changes include the way roof tile underlays (RTUs) such as breather membranes are selected in relation to the position and type of building and the way they are affected by the air pressures that can ‘balloon’ the membrane. The ‘ballooning’ can cause the membrane to put pressure on the underside of the roof covering and might dislodge the tiles or slates and has become a greater issue with the popularity of lighter membranes and an increase in extreme weather events.

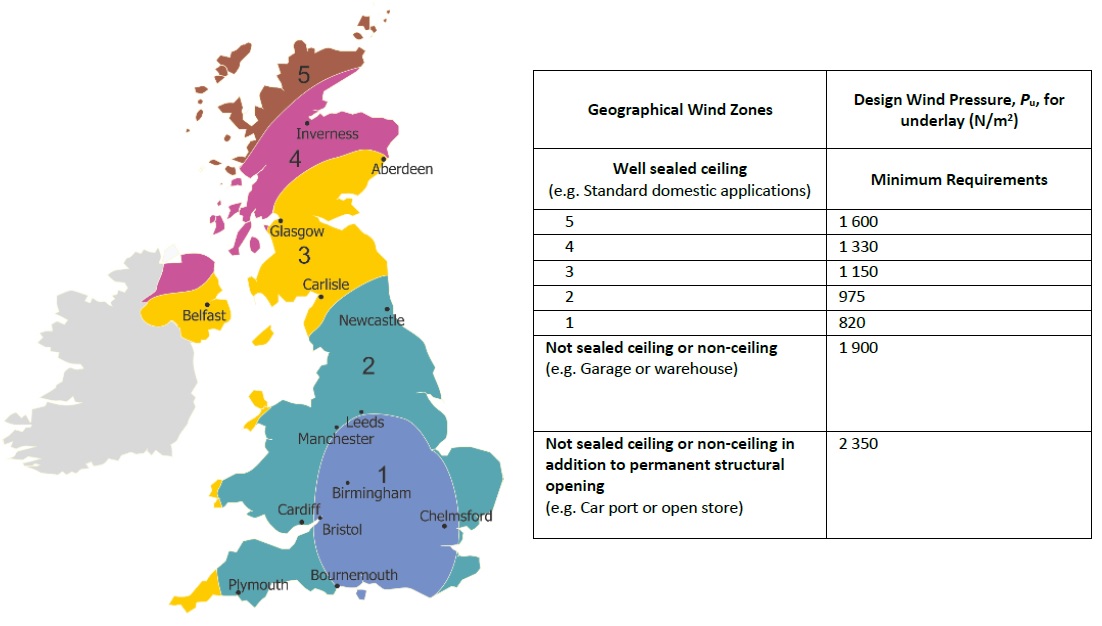

The amendment covering the testing of RTUs gives clear guidance to the specific way that membranes should be tested to resist these pressures, as well as requiring manufacturers to correctly identify and display these results on the packaging. The map below divides the UK into five wind  pressure zones and manufacturers must declare which zones their product is suitable for.

pressure zones and manufacturers must declare which zones their product is suitable for.

But local differences in topography due to height above sea level and proximity to the sea may mean that the calculations need to be adjusted and a higher wind resistance may be required. Further pressure on the membrane is calculated where there is no ceiling (e.g. a garage), where the construction is open (e.g. a car port), and where the ridge height of the building is greater than 15m. In these instances it is recommended that the manufacturer is consulted to ensure suitability of the product. This might seem fussy but you will soon come to understand which membranes are suitable for the areas you work in.

One of the key issues the standard looks at is the treatment where the membrane is lapped. It’s recommended that an intermediate (fly) batten is provided, or that the membrane is taped at joints. Fly-battening can be a health and safety issue in that it can cause a trip hazard for roofers. To avoid falling foul of the CDM regulations, we recommend that the joint is taped or that the joint is formed at the nearest natural batten.

Key considerations in BS 5534

- Where the site is above 100m above sea level, within 20km of the coast, or the ridge is over 15m high, consult the manufacturer to ensure suitability

- Each roll should clearly indicate the maximum performance of the membrane both with batten-restrained and/or taped laps. The figure must be quoted. Again – if in doubt, consult the manufacturer

- Using an intermediary (or fly) batten irregularly to restrain the lap might become a tripping hazard. Extend the head-lap down to the nearest natural batten

- The revised CDM safety regulations could now make a manager or property owner liable if an accident occurs after installing an intermediary batten

- The use of a taped lap has been shown in testing to provide a cost-effective and better-performing solution than fly battening. Each membrane should use the manufacturer’s own tape for compatibility

- Fully boarded (sarking) roofs where the butt jointed gaps are less than 3mm and any roof where the slates are nailed directly to the sarking require a membrane that has achieved a resistance of at least 820N/m2

- Remember – selecting the wrong membrane may cause the roof covering to be dislodged in high winds.

Annex A sets out an upper limit or uplift resistance of 2 350 N/m2. If you’re unsure about a membrane’s suitability, choose one with an application resistance that’s greater than this to ensure compatibility.

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

Ychwanegu sylw newydd