Getting to the point about repointing brickwork

It is generally considered that well-built brickwork requires little maintenance. However, as the brickwork ages, the surface of the mortar joints may tend to show signs of poor condition or failure – such as when the mortar is powdery and easily rubbed away or eroding so that the joints have become appreciably recessed. In this situation, you will need to decide whether there is any loss of strength in the wall and, if there is, if repointing will adequately restore that strength and make the joints sufficiently durable.

What is repointing?

Repointing is the refilling of the outer part of the joints on brickwork where the previous mortar has weathered away or has been removed because it is unsuitable. Repointing can significantly affect not only the look but also the durability of masonry. If done badly or using the wrong materials, it can damage the brickwork, sometimes beyond repair.

Masonry walls need to be able to regulate water penetration and evaporation. If the condition of the mortar joints is poor or if the wrong mortar has been used for repointing in the past, then this process can be compromised. There are three main reasons for repointing:

- Mortar joints are crumbling or loose

- Mortar joints are open or have weathered back to such an extent that the edge of the masonry units are exposed forming a ledge that encourages water to seep into the masonry

- A hard impermeable cement-based mortar has been introduced trapping moisture and accelerating the deterioration of the masonry

How does pointing affect the strength of the wall?

According to BRE Good Repair Guide 24, walls up to two storeys with failed pointing are usually strong enough structurally. However, a structural assessment is always advisable for walls of three or more storeys, and may indicate the need for other measures in addition to repointing or even rebuilding. BRE provides guidance that in a typical case:

- Halving the compressive strength of the mortar reduces brickwork strength by only about 15% and brickwork strength is negligibly affected by unfilled perpends; however

- Deeply recessed bed joints can reduce compressive strength by about one-third and lateral strength (e.g. against suction) by up to a half

There are in-situ tests for determining the strength of mortar and brickwork (e.g. the screw pull out/BRENCH tests).

The main principle to remember in deciding whether to repoint is that if the poor condition of the brickwork is due only to erosion of the mortar, repointing can restore adequate strength and rebuilding can be avoided.

How to repoint?

Pointing, or repointing as it tends to be known for work on existing buildings, should be carried out when the mortar in the joints between bricks (or other forms of masonry – stone, flint, block, etc.) begins to deteriorate and fall away. This deterioration can often be because of the effects of age, weather, and/or physical or chemical damage. If the property is old, it is worth checking if it’s a Listed Building before doing any work as Planning Permission is likely to be required before work starts, to agree on the type of mortar, etc.

Never simply brush off loose mortar and attempt to skim over the top with a thin layer of new mortar. This will not fully adhere to the joint and will have insufficient depth to withstand the effects of weathering from wind, rain, snow, frost, and sun. To correctly repoint a wall, the old mortar should be raked out (removed with a hook type tool or a special drill adaptor) to a depth of not less than 12mm and not more than 19mm. In some guides it is recommended to rake out the old mortar to a depth of around 2x the width or height of the joint that is being repointed – so, for a 10mm wide or deep joint this would be 20mm. The use of disc saws to clean or cut out joints is not recommended as a power saw can be difficult to control and can often cause damage to the brickwork itself, not to mention the risk of harm to the operative.

When preparing for repointing care should be exercised to prevent any damage to the bricks themselves and to ensure that the mortar that is to be inserted will be able to fully adhere to the masonry and the residual mortar in the joint. Consequently, the wall should be inspected and, if necessary, damped down by spraying water over the area to be worked on before commencing the repointing.

Always brush off any loose dust or residual debris after raking out mortar joints, before damping down the wall and commence work by repointing from the highest part of the wall, work down to the lowest level. It is advisable not to work from a ladder when repointing at height and only to use a competently erected scaffold platform. Always wear protective clothing and equipment when preparing for and carrying out repointing, such as safety glasses, dust mask or respirator, safety gloves, and ear defenders if using power tools.

The shape and style of the joint should match that of the old pointing (jointing), especially if it is a Listed Building. Some styles of pointing might require a trained and competent bricklayer to carry out the work, such as ‘Bead’ or ‘Tuck’ jointed pointing. In more modern properties, where the joint style is simple, a pointing gun (similar to a mastic gun) can be used to squeeze the mortar into the joint. This type of tool is useful to cover large areas of wall quickly.

Care should be exercised to ensure that the new mortar does not overfill the joint(s) and spill out and stain the wall. Excess mortar should be removed as work progresses, which can then be reused rather than allowing it to fall to the floor and be wasted. For the untrained the use of a hawk (hand-board) and pointing trowel can be tricky and it can take time to master the technique of keeping the mortar on the board whilst applying to the trowel and then inserting into the open joint. As such employing a trained professional can often be better than running the risk of wasting materials and damaging the appearance of the wall.

When undertaking large areas of repointing the work area should be limited to the safe height that can be reached using a pointing trowel and a hawk (a hand-held mortar board) or any other pointing tool. Once the joints are filled these can then be returned to later, but before the mortar has dried (set) too hard, for finishing the pointing with either the trowel or a jointing tool.

Usually, repointing should be avoided if at all possible in winter when there is danger of frost. However, if it does become essential to repoint in cold weather, the work must be satisfactorily protected against the effects of rain and wind.

Mortar appearance and mixes

It may be possible to find a sound example of the existing pointing to be matched in a sheltered part of the building, for example under the eaves or behind downpipes, particularly on north and east elevations, that is contemporary with the initial construction. For domestic buildings constructed before the early 20th century, this will almost certainly be a lime-based rather than a cement mortar. A close inspection of the mortar will help determine how the joints are finished and whether the aggregate is coarse or fine grained. There may be other additions, such as ash or bits of broken brick or shell, that contribute to the character of the mortar on period properties. This can then be used as the basis for designing a new mortar and joint finish to match the original pointing.

Mortar mixes should be carefully chosen to suit the type of brick and the exposure conditions. Choosing too strong a repointing mix, in the belief that it will be more durable and more weatherproof, is a common error. If repointing mortar is too strong, the mortar may end up cracking and the bricks may spall, especially if repointing is shallow or the original mortar is considerably weaker.

Mortar mix that is compatible with the permeability of the particular brickwork in the wall and suitable for the degree of exposure should be chosen. The key principle is that the mortar should be slightly weaker and more permeable than the brick. Mortar that is less permeable than the masonry will prevent moisture from evaporating out through the joints. Instead, moisture will move largely through the bricks, increasing the rate of decay and leaving the hard mortar standing proud.

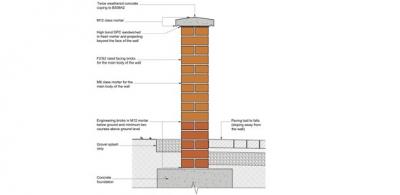

Figure 2: Damaged brickwork after repointing due to specifying incorrect mortar mix

Mortar that is harder than the masonry is at risk of cracking and causing mechanical damage to the bricks. For this reason the inclusion of any cement-rich mixes should be avoided where the original pointing is lime based. It is important to replace lime mortar with lime mortar to maintain the ‘breathability’ of the wall fabric. A modern mortar mix sets harder and is resistant to rain penetration so will in effect ‘suffocate’ an old building; moisture that was drawn out of a wall through the seams of lime mortar will be trapped, causing dampness in the walls. The moisture will find an alternative route out, possibly to the interior, and the damp masonry will be vulnerable to damage from frost and corrosive salts. Many builders believe, wrongly, that they can make an effective lime mortar by adding cement to give greater strength and a quicker set, but in fact, low-cement mortars are less durable than pure lime mortars.

Advice on the appropriate mortar for a given application is detailed in PD 6697 and BS EN 1996-2.

NOTE: Every care was taken to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the dutyholder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

Getting to the point about repointing brickwork

Submitted 1 year 4 months ago

Ychwanegu sylw newydd