Cavity wall tie ‘sound’ installation

We recently wrote about good installation of cavity wall ties in masonry walls in relation to moisture ingress and structural failure. There are some additional areas where the specification of a wall tie is critical, including their correct specification and installation to resist sound in separating walls between dwellings.

In 2002, the Building Research Establishment released an information paper (IP 14/02) ‘Dealing with poor sound insulation between new dwellings’. This highlighted a reason for lower-than-expected sound insulation as incorrect wall tie specification/installation between dwellings, causing a drop in performance by as much as 5dB. The 5dB could mean the difference between a pass and fail on a pre-completion sound test and result in costly or intrusive remedial works.

It is therefore crucial to understand what ties are required in separating walls between dwellings and how to identify this on site. This is only possible by understanding why the wall tie can impact the sound performance of the wall.

Paragraphs 2.18-2.24 of Approved Document E in both England and Wales give guidance on wall ties to be installed within separating and external cavity masonry walls. This splits the cavity wall ties into two types, A or B; however, for separating walls between dwellings, paragraph 2.66 of the Approved Document requires use of a ‘tie type A’.

Tie type A

Paragraph 2.19 of Approved Document E defines this type of tie as being either:

- Butterfly ties in accordance with BS 1243:1978 for cavity widths 50mm-75mm and minimum masonry leaf thickness of 90mm; or,

- Wall ties with an appropriate measured ‘dynamic stiffness’ for the cavity width.

- Wall ties will also need to achieve structural requirements, it is therefore likely that ties with an appropriate measured ‘dynamic stiffness’ will be needed for new separating wall construction.

What is dynamic stiffness and why is it important?

Dynamic stiffness is a measure of the ability of a wall tie to transmit vibration (sound). Wall ties with a high stiffness will transmit more vibration than those with low stiffness. To understand this in more simple terms, think of a guitar string - if this is loose or slack no noise would be heard when strummed, but when tightened a sound is heard because of the vibration in relation to its stiffness. It also follows that the length of the string would affect how well the sound is transmitted.

Therefore, wall ties with a low stiffness or over a larger cavity are less likely to transmit sound than those that are more rigid or over a shorter distance. It is essential that cavity ties assessed over a larger cavity width are not used on a smaller width as this will increase the dynamic stiffness and transfer more sound.

This dynamic stiffness is assessed by the force transferred in meganewtons (MN) for a particular cavity width in metres (m) and would be quoted as a figure in MN/m. It is important to select wall ties that are suitable for the width of the cavity proposed in accordance with manufacturer’s details. If there is any variance to the intended cavity width, further advice should be sought from the designer and agreed with building control.

What is the appropriate ‘dynamic stiffness’?

The dynamic stiffness of an individual tie over a certain cavity width is important but does not give the full picture. The number of ties in an area (the density) will also have an impact as the more there are, the more paths there are for sound to transfer between the two leaves of the wall and therefore greater potential for sound transmission.

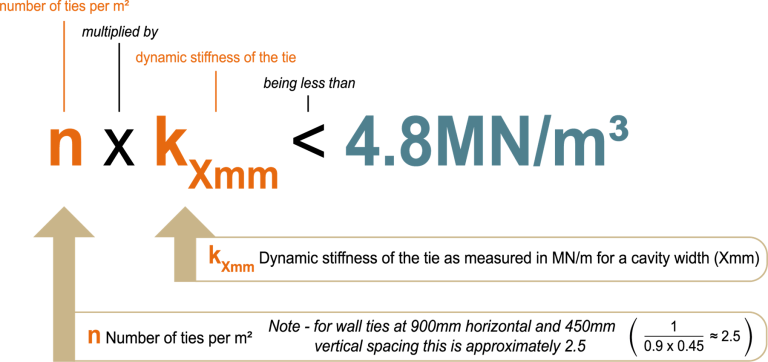

Paragraph 2.19 of Approved Document E therefore gives the ‘appropriate’ dynamic stiffness for a particular cavity width as:

The number of ties per m² for wall ties at minimum 900mm horizontal and 450mm spacing is approximately 2.5. For this type of wall, multiply 2.5 by the dynamic stiffness of the tie and this should be less than 4.8MN/m³. It must be remembered that wall ties installed at smaller distances will have a greater density and could result in an overall figure above 4.8MN/m³ and special consideration will be needed to maintain performance.

What do I need to remember?

When designing or constructing separating masonry walls between two dwellings, the approved design specification should always be followed. Any changes should be agreed with the designer in discussion with the building control authority to avoid potential issues.

Key points to remember:

- Wall ties can affect the performance of a wall by up to 5dB and this could be the critical difference between a pass or fail on a sound test.

- For separating walls, wall tie type A should be used appropriate for the width of the cavity as specified. Robust Detail have provided more detail on the Type A Wall Ties.

- Always check the approved specification against the product supplied to ensure the right tie for the cavity width is being used and report any discrepancy.

- Ensure the distance between the wall ties or the width of the cavity do not vary from the design specification.

- Ensure the wall ties also meet the structural specification and are installed with good workmanship.

Does this apply for Robust Details Specifications?

If details published by Robust Details Ltd are being used in place of pre-completion sound testing, the specification for wall ties in cavity separating walls should be in accordance with the relevant specification as given by Robust Details in their handbook.

Please Note: Every care was taken to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the dutyholder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

Ychwanegu sylw newydd