How to get it right: Notches & holes in solid timber joists

When installing pipework or cabling, floor or ceiling joists may need to be notched or drilled. But this could weaken the floor to such an extent that it becomes structurally unsound.

To find out if this might be the case, you can find guidance on notches and holes in solid timber joists for use in domestic properties in section 3.2.2 of Eurocode 5 published by BM TRADA.

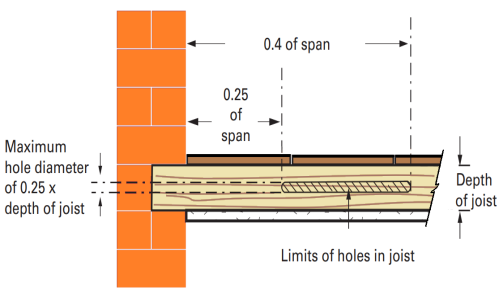

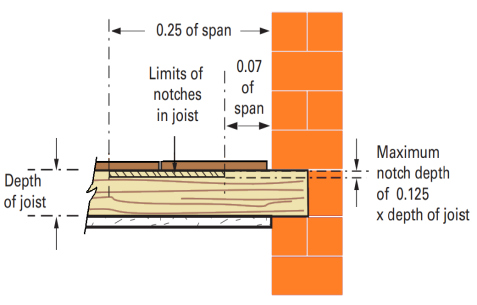

The diagrams and tables below illustrate the zones and sizes permissible for differing spans and joist depths.

| Span of timber | Hole locations between | Notching locations between | ||

|---|---|---|---|---|

| mm | 0.25 of span | 0.4 of span | 0.07 of span | 0.25 of span |

| 2000 | 500 | 800 | 140 | 500 |

| 2500 | 625 | 1000 | 175 | 625 |

| 3000 | 750 | 1200 | 210 | 750 |

| 3500 | 875 | 1400 | 245 | 875 |

| 4000 | 1000 | 1600 | 280 | 1000 |

| 4500 | 1125 | 1800 | 315 | 1125 |

| Depth of timber | Max hole diameter | Max notch depth |

|---|---|---|

| mm | 0.25 x depth mm | 0.125 x depth mm |

| 100 | 25.0 | 12.5 |

| 125 | 31.3 | 15.6 |

| 150 | 37.5 | 18.8 |

| 175 | 43.8 | 21.9 |

| 200 | 50.0 | 25.0 |

| 225 | 56.3 | 28.1 |

| 250 | 62.5 | 31.3 |

| 275 | 65 (max) | 34.4 |

| 300 | 65 (max) | 35 (max) |

Key points for notches and holes

Before you start work check that the joist size is adequate for the span.

Notches can only be made in the top OR bottom of the joists, (not both) within the permitted area to a maximum of 35mm.

Holes may only be made on the joist's centreline within the permitted area to a maximum diameter of 65mm.

Additional holes must be at least three diameters (centre to centre) apart.

Single/multiple timber structural beams, rafters, purlins and binders must never be notched or drilled without calculations to justify the remaining timber. Rafters may be birdsmouthed by no more than 1/3rd of the depth.

This guidance does not apply to engineered joists e.g. JJI joists and reference should be made to specific product manufacturers instructions.

Further reading

How to get it right: Supporting joists on external walls

Please Note: Every care was taken to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the dutyholder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.

This article was reviewed and updated on 10 August 2023

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

drilling of joists

Submitted 6 years 5 months ago

2m span .4 X span 880 not 8800

Reply

Submitted 6 years 5 months ago

Thanks for the spot - we've amended that.

Regards,

Julie, LABC

table correction

Submitted 6 years 4 months ago

Reply

Submitted 6 years 4 months ago

Calculating notch

Submitted 5 years 1 month ago

Reply

Submitted 5 years 1 month ago

Thank you for your query.

As noted in the diagram and table above, which is taken from guidance published by BM TRADA, notches should not be cut closer to the support than 0.07 of the span.

Kind regards,

Dalila, LABC

Template for notches and holes in joists

Submitted 4 years 11 months ago

Floor joists

Submitted 4 years 2 months ago

Floor Joists

Submitted 2 years 10 months ago

LABC response

Submitted 2 years 9 months ago

Thank you for your enquiry.

Notches should not be deeper than the lesser of 0.125 times the depth of a joist or 35mm, and should not be cut closer to the support than 0.07 of the span, nor further away from the nearest support than 0.25 times the span. Each end of the joist may be edge notched at either the top edge or the bottom edge. We would recommend that if the ends of the joists are notched the notch should be within the depth limits mentioned – which would suggest for a 200mm deep joist a notch of <=25mm. As such we recommend that you seek independent professional structural engineering advice in relation to the bearing depth having been reduced and what, if any, likelihood there might be of the risk of shear failure.

Best,

LABC team

Add new comment