How to get it right: Supporting joists on external walls

It is now a requirement to limit air leakage from the inside of buildings – one main area where this situation can be improved is to effectively seal the gaps around floor joists where they bear into the external walls. This can be done in two ways:

Joist hangers

Only proprietary joist hangers complying with BS 6178 Part 1 1999 or BS EN 845-1 can be used subject to the manufacturer’s recommendations but generally these will include:

- The hangers must be of the correct type for the strength of the blockwork being used.

- The back plate of the hangers must be in contact with the face of the blockwork for the whole height of the hanger, and the hanger must be vertical.

- Joists must be accurately cut to length – the maximum overall tolerance is 6mm.

- Don’t load joists until at least 3 courses have been built over the hanger flange and the mortar has set.

- Remember where the wall supporting the joists is over 3m long, special “restraint” type hangers (to BS 5628: Part 1) are required at a maximum of 2m centres, to provide lateral restraint to the wall itself.

Typical joist hangers Restraint type hanger

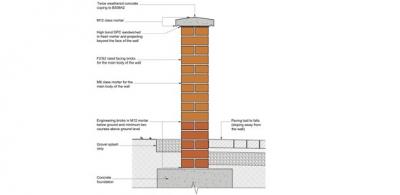

Building in the joists

Building in joists is acceptable provided that;

- The wall itself isn’t a party wall. It is unlikely the wall would pass the required sound tests.

- The joist is accurately cut to length so that while it does not extend into the cavity, it is fully supported by the full width of the blockwork it’s bearing onto.

- The masonry is accurately cut to allow an even mortar joint (of between 10mm and 15mm) all the way around the sides and tops of the joist. The mortar joint is to be struck or recessed, so that a good bead of silicon mastic between the blockwork and the joist can be added later. This must be sufficiently generous to cope with any anticipated shrinkage in both the masonry and the timber.

- The blockwork supporting the joists is built level. Ideally packers shouldn’t be used, but slate packers are acceptable provided they are the same bearing width as the joist, aren’t more than 15mm thick and are recessed to the same depth as the mortar joint to receive the silicon mastic bead afterwards.

- The silicon mastic bead must be installed after both the joists and the masonry are reasonably dry. Ideally this should be done after the roof has been installed.

However, please note...

- The use of expanding foam products is not acceptable as an alternative to silicon mastic.

- Special arrangements will need to be agreed when using laminated or timber engineered joists, as they do not have “square” ends. Generally, loose fitting packer pieces fixed in place with silicon mastic can be used to “square” up the ends, but please agree this with your Building Control team first.

- The use of proprietary end caps can eliminate air leakage problems associated with timber shrinkage

Don’t forget to let your Building Control team know once the silicon mastic has been installed, so that we can confirm this is satisfactory prior to being covered over.

Interested in this?

Browse our 'How to get it right' articles

Please Note: Every care was taken to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the dutyholder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

Just look at the state of the brickwork in the picture!!!!

Submitted 6 years 4 months ago

The PIcture

Submitted 4 years 10 months ago

Joisted floor

Submitted 4 years 2 months ago

If a joisted floor is sat straight onto blockwork rather than hung of hangers.

What is the name of this style of construction?

Style of construction

Submitted 4 years ago

Add new comment