How to prevent precipitation damage to external walls

Building regulations require external masonry cavity walls to resist the penetration of precipitation (rain and snow) to the inside of the building and to prevent it affecting parts of the building that may be damaged by moisture if it would be detrimental to the health and safety of people using the building.

The outer leaf of most brickwork cavity walls will permit water to enter the cavity when it is subjected to persistent wind-driven rain, usually through cracks at the junction of the brick and mortar. If the wall is built correctly, water will flow down the inside face of the outer leaf and run out of the cavity through the weepholes.

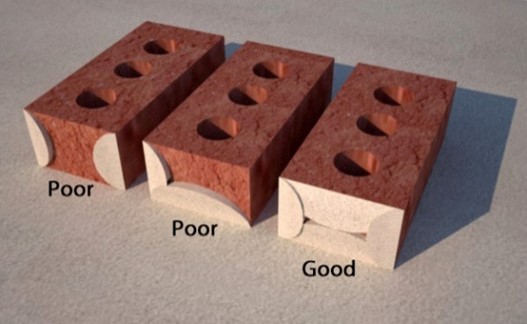

Even so, the extent of water absorption should be limited, and guidance is given in Approved Document C to the building regulations requiring bricks to be laid on a full bed of mortar and the cross joints substantially and continuously filled. This is also necessary to ensure the structural integrity of the wall.

Bed joints should be level and you should avoid excessive furrowing.

Cross joints, more commonly known as perpends, should be filled by spreading mortar evenly across the entire end face of the masonry unit. Often bricks are tipped and tailed where mortar is applied to the front and rear edges of the brick only. This practice is unlikely to comply with building regulation guidance.

Brickwork cavity walls sometimes contain defects which allow water to pass across and then through the inner leaf causing dampness to appear on the inner surface.

Deposits of mortar on wall ties and damp-proof courses, and mortar extrusions on the inside face of the outer leaf, particularly at bed joints, can deflect or transmit water to the inner leaf.

Incorrectly installed wall ties can act as a route for water to pass across the cavity. They should always be bedded horizontally and never slope down towards the inner leaf.

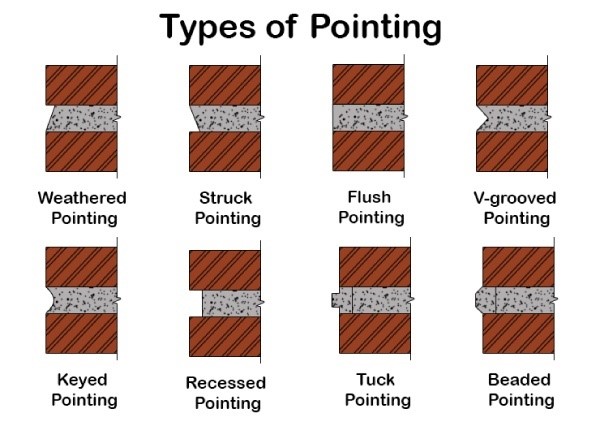

The effectiveness of the brickwork wall is dependent on pointing the brickwork and the mortar joint profile chosen.

(picture from tutorialstipscivil.com)

Pointing as the work continues is preferable to pointing at a later stage. Correct tooling compacts the mortar in the joints and helps improve durability. Recessed and flush joint profiles can sometimes be used but to provide the greatest resistance to rain penetration, joints should be formed with either a weather struck or bucket handle profile.

Thermal insulation within the cavity wall can also be a route for water penetration across a cavity wall and so needs to be correctly installed. Water can be transmitted across the cavity through voids or gaps in the insulation or via mortar extrusions or droppings at insulation board joints whether the insulation is waterproof or not.

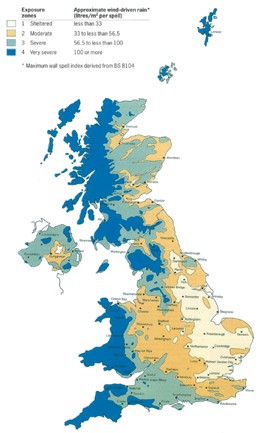

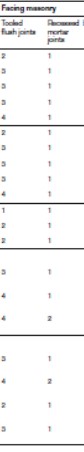

The building regulations allow insulating materials to be placed into a cavity but along with the suitability of the insulation product, the joint profile of the brickwork external face should either:

- follow the recommendation below for the building’s location or

- contain evidence of the suitability of the brickwork and insulating product’s combined performance issued to Local Authority Building Control

- Where local conditions accentuate wind effects, such as open hillsides or valleys where wind is funnelled onto the wall, add one to this exposure zone value

- Where walls do not face into the prevailing wind, subtract one from this exposure zone value

Please Note: Every care was taken to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the dutyholder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

Add new comment