Airtightness performance standards for new buildings

The building regulations require new buildings to be constructed within a range of airtightness performance standards to ensure that the infiltration and leakage of air between the inside and outside of the building is at an acceptable level.

When a building is being heated and the temperature outside is lower than that inside, the heat loss through air movement should be acceptable if this performance is achieved.

The regulations also require new windows and doors installed in existing buildings to be suitably draughtproofed.

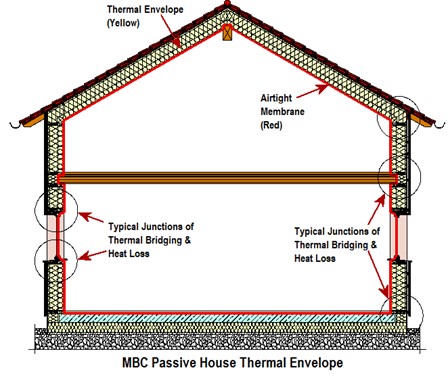

The concept of the air-tight barrier for a building is shown in the diagram below. It is a continuous membrane on the warm side of the thermal insulation envelope. The junction between the window or door and the wall can be a weak spot if sealing is not correctly detailed and applied.

Most standard door sets, and windows are manufactured with appropriate weather-stripping which should provide adequate airtightness for the fitting itself. Gaps around them need to be sealed against the building structural opening, however; otherwise, the gap between can provide a route for air movement. When fitting window or door frames consideration should be given to providing appropriate seals at the head, jambs and sill and threshold.

Air infiltration can be significantly reduced by sealing the gap internally between the frame and surrounding structural opening. This is especially important where a drylining is used.

Thermal Envelope of Passive House (image from mbctimberframe.co.uk)

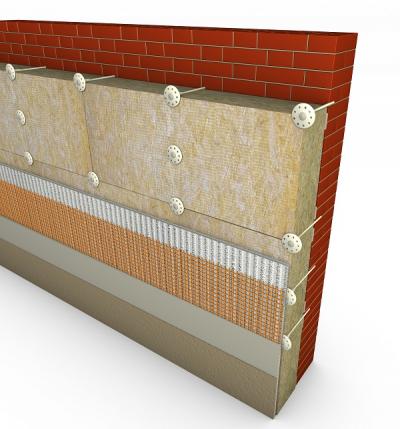

There are various methods of sealing gaps around windows and doors. Impregnated foam strip seals which either rely on the strip being compressed between the fitting and the structure or are pre-compressed and expand to fill the gap between the fitting and structure are common.

Expanding sealants are available that can be used without the need to apply a secondary weathertight seal. An alternative is to use a polyethylene foam backer strip but this would require a secondary seal as a weather seal. You should always follow the manufacturer’s installation instructions.

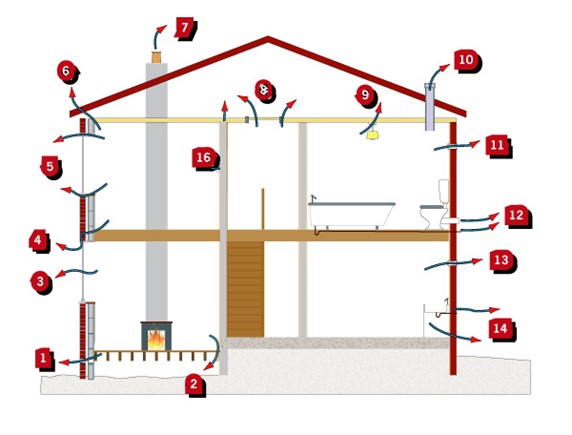

Air Sealing | Evergreen Home Performance | Maine (image from evergreenyourhome.com)

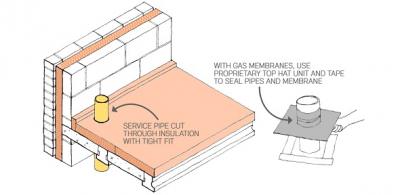

New service penetrations through the air-tight barrier should also be sealed. Examples include overflow pipes, waste pipes, flues, air-vents, ventilation ducts, cold water pipes serving outside taps and incoming gas mains passing through external walls. Some services need additional sleeving, which creates the potential for further air-paths.

The gap between the sleeve and the surrounding structure at the air-tight barrier position needs to be sealed, as does the gap between the sleeve and the service installation.

Safe use of LPG at small bulk installations (image from hse.gov.uk)

Differential movement of materials needs to be considered when specifying and applying sealing materials. Manufacturer’s recommendations should be followed for compatibility of the seal for allowing thermal movement between the materials comprising the surrounding structure and air-tight barrier and the service penetration or sleeve without causing failure of the seal. Sealing with mortar or plaster is often done but this can leave hairline cracks after drying out or when materials expand at different rates. The seal should also adhere to the materials forming the gap to be sealed.

The size of gap to be sealed is also an important consideration for a seal to perform successfully. The use of backer materials or ridged materials may be needed to reduce the gap dimension or form a regular gap where the service penetration opening is irregular in shape. Any materials used to frame a hole to be sealed should be impermeable to air itself. The use of materials such as mineral wool is not appropriate for this task.

The application of sealant around electric cables can have a detrimental effect on the insulating sheathing of the cable. It is important to refer to the manufacturer’s information to determine that the performance of electric cables is not compromised by their sealant.

Socket and switch back boxes or other electrical fittings that penetrate the air-tight barrier should also be properly sealed. The cable should be sealed where it enters the box as should any gaps in the box. Recessed lighting within a ceiling that is forming part of the airtight barrier need to be sealed to prevent air leakage.

The diagram below indicates some common breaches of the air-tight barrier.

Smartheat - Home (image from homeenergysaving.ie)

- Under floor ventilator grilles

- Gaps in and around suspended timber floors

- Leaky windows or doors

- Pathways through floor/ceiling voids into cavity walls and then to the outside

- Gaps around windows

- Gaps at the ceiling-to-wall joint at the eaves

- Open chimneys

- Gaps around loft hatches if these coincide with the thermal envelope and air-tight barrier

- Service penetrations through ceilings if these coincide with the thermal envelope and air-tight barrier

- Vents penetrating the ceiling/roof

- Bathroom wall vent or extract fan

- Gaps around bathroom waste pipes

- Kitchen wall vent or extractor fan.

- Gaps around kitchen waste pipe

- Gaps around floor-to-wall joints

- Gaps in and around electrical fittings in hollow walls

It is always important to check whether the service penetration requires fire resistance or an acoustic performance and the appropriate product chosen.

Please Note: Every care was taken to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the dutyholder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

Add new comment