Identifying the correct type of floorboard and plasterboard in domestic properties

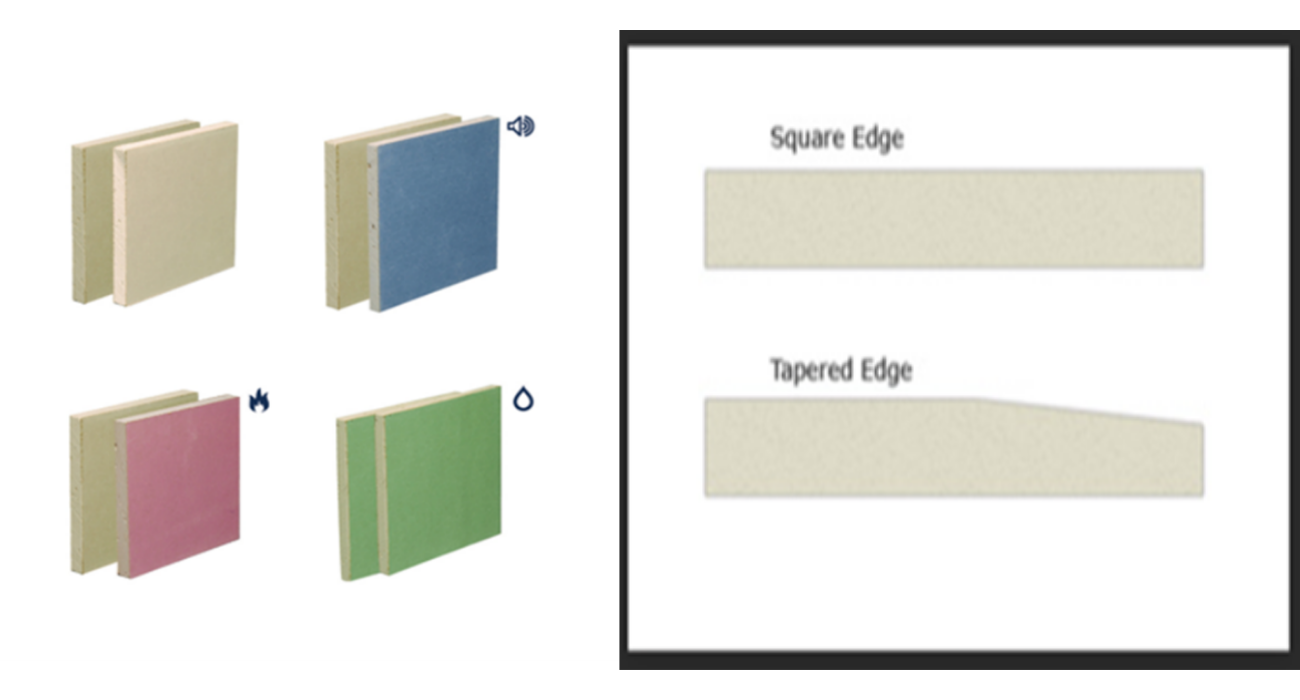

Plasterboard

Most modern houses and extensions or refurbishments use plasterboard for internal walls or ceilings instead of the traditional wet two coat plaster (although this is still common in historic buildings and repairs).

Plasterboard first appeared in the UK in 1917 and it has developed into several different specific types and uses. Read on to find out how to identify them and where to use them.

- Wall Board. These boards can be provided with a skim coat of finish plaster (ivory face) or decorated directly on to the board by a misting coat of paint followed by the decorative coat. The tapered joints allow you to fill them with the appropriate jointing compound for a smooth finish.

- Sound Reduction or Acoustic Plasterboard.

- Fire Board.

- Water Resistant Board.

Make sure you understand the required levels of fire resistance, sound insulation and thermal performance if you are building, extending, or renovating. If you don’t have approved drawings to work to, you’ll need to refer to Approved Documents B, E and L as well as manufacturer’s details. Boards can also incorporate a vapour barrier (this has a metallic film on the inner face of the board and is used in rooms that may produce condensation, e.g. bathroom, kitchen, utility room or gym)

If you are working on residential buildings over 18m, specialist advice is required to comply with the Building Regulations around the use of specialist non-combustible cement particle (CP) boarding in facades or smoke shafts.

Chipboard flooring

Chipboard or Oriented Standard Board (OSB) has been in use, in place of narrower floorboards, since the 1950’s in the UK and was first manufactured in Germany in the 1940’s. It is strong, durable. It’s commonly used in homes and again it is important to use the correct board in the right location. The British standard BS EN 312 provide the following seven grades:

- P1: General purpose boards -dry conditions

- P2: Interior fitments inc. furniture – dry conditions

- P3: Non-loadbearing-humid conditions

- P4: Loadbearing- dry conditions

- P5: Loadbearing – humid conditions

- P6: Heavy duty loadbearing – dry conditions

- P7: Heavy duty – humid conditions

(source Trada, Wood panel Industries and timber trade federations)

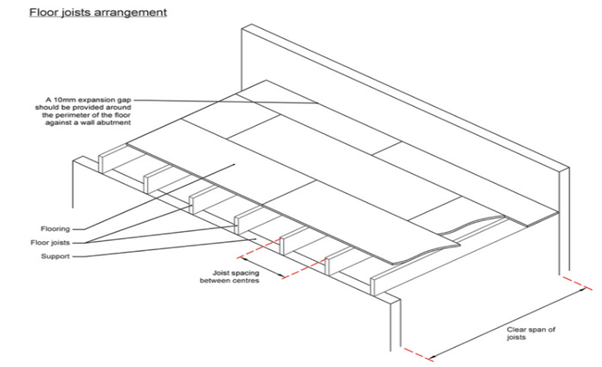

Domestic floors can be supported by timber floor joists or as a floating floor and so P4 or P5 are required. Boards are available at 18mm and 22mm (see section 10.4.1 of the LABC Warranty Technical Manual for full details and extracts as below in diagrams 1 and table 2 below) )

The P6 and P7 are intended for use in commercial premise (e.g. storage floors)

Note that the flooring grades mean that tongue and grooved boards are required to meet the structural, fire and acoustic standards in the Approved Documents. The manufacturer’s details need to be followed in terms of fixings and finishes

These conditions relate to internal flooring use only: specialist boards are required for roofing, shuttering or external cladding.

Diagram 1

Particle Boards

Acceptable particle boards consist of Orientated Strand Board (OSB) or chipboard. Chipboard should be tongue and grooved and all joints glued. The boards should be laid so that the shortest length is laid parallel to the span. OSB boards should be type 3 or 4 to BS EN 300 and should be laid with the major axis at right angles to the joists. (The major axis is indicated on the OSB board by a series of arrows) Boards must have a minimum thickness as indicated in the table below.

Particle boards should be either screwed or nailed to the joists at 250mm c/c. Nails should be annular rink shanks that are at least 3 times the depth of the board.

A 10mm expansion gap should be provided around the perimeter of the floor against a wall abutment.

Table 2.

Particle floor boarding: Minimum thickness and centres of support.

| Thickness (mm) Chipboard | Thickness (mm) (OSB) | Maximum span (mm) | Typical nail fixing (mm) |

|---|---|---|---|

| 18 and 19 | 15 | 450 | 60mm annual ring shank |

| 22 | 18 and 19 | 600 | 65mm annular ring shank |

Sound resistance

Internal floors shall, where necessary, be designed and constructed to have adequate resistance to the transmission of sound to meet the requirements of the Building Regulations.

The resilient layer and subsequent floor make up should be suitable to support the design loads. Any point loads or additional loading may have special requirements.

Floor make up laid above a resilient layer must be isolated from the walls and skirtings by the insertion of a resilient layer to meet the requirements of the sound resistance design.

Approved Document C (resistance to moisture) advises that in areas such as kitchens, utility rooms and bathrooms where water may be spilled, any board used as a flooring, irrespective of the storey, should be moisture resistant. In the case of chipboard it should be of one of the grades with improved moisture resistance specified in BS 7331:199091 or BS EN 312 Part 5:199792. It should be laid, fixed, and jointed in the manner recommended by the manufacturer. To demonstrate compliance the identification marks should be facing upwards.

Please Note: Every care was taken to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the dutyholder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

Add new comment