Can you identify fire resistant glass?

Recent reports have suggested there may be a number of non-compliant or ‘fraudulent’ fire-resisting glass and glazing materials on the market. This glass is critical for life safety and it is vital for you to be able to understand and recognise the key features of this type of glazing.

Understand the marks on fire resistant glass

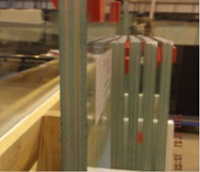

The cross sectional area of the glass is especially important. Note the multiple layers in the second picture below, and the marking, which must be on every piece. In all cases, the brand name is at the top, the standard (EN14449) and impact rating (2B2) is in the middle, with the supplier name at the bottom (CGII).

This does not comply

• Non-compliant 11mm ‘fire-resistant’ glass

• Non-compliant 11mm ‘fire-resistant’ glass

• panes of 5mm float glass

• layer of 1mm standard PVB (non fire-resistant)

• Independent tests have confirmed the material does not meet the fire-resistant standards and, in some instances, may assist the growth of fire due to the materials it is constructed from.

This does comply

• Genuine 11mm Pyroguard Fire Glass

• Genuine 11mm Pyroguard Fire Glass

• 3 panes of 3mm float glass

• 2 layers of 1mm fire-resistant resin

• There are two Pyroguard products of this composition which offer 30 mins integrity and 60 mins integrity.

Genuine Pyroguard stamp

This is an example of a genuine Pyroguard stamp used by CGI International and approved processing partners to confirm that a product is certified for use in a specific fire-rated application.

This is an example of a genuine Pyroguard stamp used by CGI International and approved processing partners to confirm that a product is certified for use in a specific fire-rated application.

Further information

View Building Regulations Document B.

Also read What's the difference between fire proof and fire resistant?

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

Add new comment