Can I build over a gas service pipe?

Whilst digging the excavations for an extension to a dwelling, you uncover a gas service pipe in the trench. The layout of the extension would result in this gas service pipe now being located underneath the extended dwelling. What should you do? This article will help you understand the issues.

Figure 1: Gas pipe in foundation (photograph courtesy of myhouseextension.com)

When a gas service is initially installed into a dwelling, it should have been installed to the relevant gas industry standards.

The current standard construction technique applied by the UK gas industry for meter positions terminating externally, typically means that the gas service pipe connecting your meter to the gas main in the street is made from polyethylene (PE). Gas pipes are generally laid directly in the ground, although in certain soils selective backfill may have been used as a bed and pipe surround and, on occasion, pipes may be laid in ducts. Ductile iron pipe will sometimes be found wrapped in loose-fit polyethylene sleeving as protection against corrosion. Polyethylene mains may be inserted into redundant iron gas mains and polyethylene service connection pipes may be inserted into yellow convoluted ducting on new housing estates.

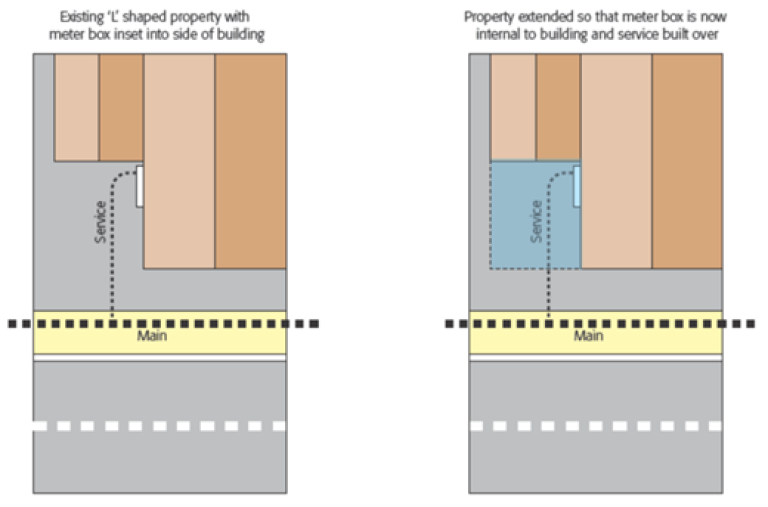

Over time, alterations or extensions may be made to a dwelling which results in:

- the polyethylene gas service pipe being located within the footprint of the extended dwelling, and/or

- the gas meter and regulator being located internally within the dwelling

An example of the above is shown below in Figure 2a and 2b.

Figure 2a: Figure 2b:

Figure 2a: Before extension built (courtesy of Gas Safe Technical Bulletin 003)

Figure 2b: After extension built (courtesy of Gas Safe Technical Bulletin 003)

Figure 2b may result in the installation being classified as ‘not to current standards’ or ‘at risk’ by the Gas Transporter (GT).

Gas Industry Unsafe Situations Procedure

In accordance with the Gas Industry Unsafe Situations Procedure (GIUSP), if the dwelling is supplied via:

- a low pressure (LP) fed gas service and it is discovered that it has been built over, the installation may be classified as ‘not to current standards’

- a medium pressure (MP) fed gas service and it is discovered that it has been built over, the installation may be classified as ‘at risk’. This is because the increased risk associated with elevated gas pressures

If the pressure is unknown, then in the interests of gas safety, an ‘at risk’ classification should be applied to the installation. However, in both situations, the Gas Transporter should be notified immediately, and their instructions followed. Failure to follow their instructions, may result in the gas supply being capped off.

Why is building over a gas service pipe dangerous?

Polyethylene gas service pipes are not designed to be installed underneath or within a dwelling for the following reasons:

- where there is a wall, footing or foundation built over a polyethylene gas service pipe this causes a potential weak spot, and polyethylene pipe may not have adequate integral strength to support these loadings or any building movement that may happen over time

- polyethylene pipe is built to be used underground with an adequate amount of ground cover, where the polyethylene pipe does not have adequate ground cover this may be susceptible to damage from other external forces, corrosive chemicals or changes in temperature

- polyethylene gas pipe has no fire resistance and therefore if there was a fire the polyethylene pipe can melt at low temperature

All the above situations can lead to a gas escape within the dwelling and/or fuel fire, which may result in serious damage to the property.

Planning an extension?

Where it is planned to build an extension to an existing dwelling, which will be built above a gas service pipe or result in the gas meter being located internally, you should seek permission from the relevant Gas Supplier and Gas Transporter to relocate the gas services and/or meter installation prior to the building works commencing. You can find out who your:

- Gas Transporter is by visiting www.energynetworks.org and searching here using your postcode

- Gas Supplier is by visiting www.findmysupplier.energy and searching using your postcode

For more information, please see Gas Safe: Technical Bulletin 003 and GTC: Built Over Low-Pressure Gas Service Pipes.

HSG47: Avoiding danger from underground services

Even if you are not building over a gas service pipe, you must still be careful when excavating near them.

In HSE guidance HSG47: Avoiding danger from underground services, it explains the three basic elements of a safe system of work needed during excavations:

- planning the work

- locating and identifying buried services

- safe excavation

Adopting a robust safe system of work, as outlined in HSG47, should allow below ground gas service pipes to be identified prior to works commencing and ensure the works are undertaken in a safe manner. HSG47 also provides further information that may be useful to you if working near gas service pipes, some of which is summarised below.

Damage to gas pipes and connections can cause leaks that may lead to fire or explosion. Typically, there are two types of damage that may occur:

- damage that causes an immediate leak

- damage that causes a leak sometime later, for example poor reinstatement may leave a pipe inadequately supported or subject to unequal forces

Figure 3: Aftermath of a gas explosion, following damage to an underground gas service pipe

(photograph courtesy of HSE)

The risk from leaking liquified petroleum gas (LPG) is greater than from a natural gas leak as it is heavier than air and does not disperse so readily. It can also travel great distances below ground level before accumulating at low level, for example in basements and cellars.

Consider the location of underground gas pipelines when planning building, excavation, landfill, or other such work. Such activities may either cause damage to the pipelines or deny access to them for maintenance purposes. Make suitable arrangements for future access and maintenance before undertaking the work.

Anyone who carries out work near underground gas pipes and associated equipment should observe any specific requirements made by the Gas Transporter, and make sure that access to the equipment is always available. Do not make any unauthorised repairs to gas pipes. If in doubt, seek advice from your Gas Transporter.

Where gas pipes run alongside excavations, changes in backfill etc may cause differential ground settlement and increased stress in the pipe. Wherever an excavation may affect support for a gas pipe, consult the Gas Transporter as it may be necessary to divert the gas pipe before work begins.

Markers may have been used to indicate gas services, namely:

- marker tiles, which may have been used above gas pipes; for example, when they have been laid at shallow depths such as above cellars

- coloured plastic markers, including for polyethylene mains

- marker posts/plates, which may show the position and size of valves or test points on gas mains

However, such markers may have been disturbed and you should not rely on them as an accurate indicator of position.

Locate polyethylene gas pipes by hand digging before mechanical excavation begins. This may also be necessary for metallic pipes if they have not been successfully located by a pipe-detecting device. This is particularly important for service connection pipes, which will not be marked on plans. A suitable hand-digging method is to dig a trial trench along the road near the kerb or in the footway where the service connection pipes are likely to be at their shallowest. When the position and depth of the pipes have been determined, work can proceed.

Gas pipes may have projections such as valve housings, siphons and standpipes that are not shown on the plans. To allow for this, do not use mechanical excavators within 500mm of a gas pipe. The Gas Transporter may advise greater safety distances, depending on the pipeline pressure.

The Reporting of Injuries, Diseases and Dangerous Occurrences Regulations (RIDDOR) 2013

These regulations require employers and the self-employed to report certain occupational injuries, diseases and dangerous occurrences to the relevant enforcing authority (for incidents arising during excavation work this will almost certainly be the Health & Safety Executive via an online reporting system). Certain pipeline incidents, including gas escapes, may be reportable as ‘dangerous occurrences’ – see here for more information.

Please Note: Every care was taken to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the dutyholder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.

Sign up to the building bulletin newsletter

Over 48,000 construction professionals have already signed up for the LABC Building Bulletin.

Join them and receive useful tips, practical technical information and industry news by email once every 6 weeks.

Subscribe to the Building Bulletin

Comments

Add new comment